Noticias

ENE 19 2016 l asce.org l Catherine A. Cardno, Ph.D

World’s first floating wind farm to be built off scottish coast

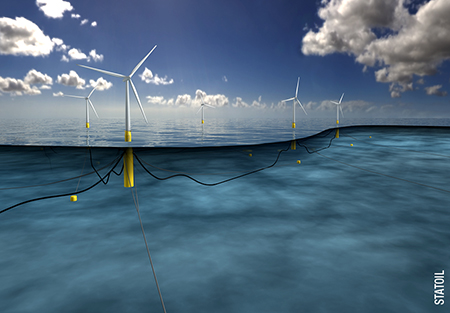

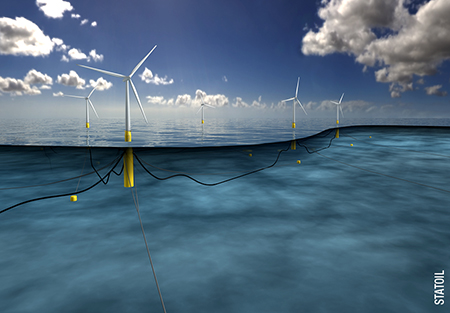

A 30 MW wind farm floating in 4 sq km of water that is 95 to 120 m deep will be constructed in the North Sea, 25 km off the coast of Peterhead, Scotland. The world’s first such floating wind park will serve as test bed for future installations. Statoil

The floating wind farm will be built by global energy company Statoil as an industrial-sized, proof-of-concept pilot test for the commercial production of such wind parks.

Last year was a record year for wind energy generation in the United Kingdom, and records were set in weekly, monthly, quarterly, and annual wind generation measurements, according to the renewable energy trade association RenewableUK. In all, the association reports that 11 percent of the United Kingdom's electricity was generated by wind in 2015—up from 9.5 percent in 2014. That percentage has the potential to rise even further in the future, if the global energy company Statoil's new floating wind farm—the world's first—proves as successful as hoped. The project is a proof-of-concept for the commercialization of floating turbine wind generation.

The NOK2-billion (U.S.$227-million) Hywind project has been approved by the Scottish government and will be built in the North Sea, 25 km off the coast of Peterhead, Scotland, in an area known as Buchan Deep. Dubbed a "pilot park," the 30 MW wind farm will cover 4 sq km and float in water that is 95 to 120 m deep.

Floating wind farms unlock the potential to create power-generating windmills in waters that are up to 700 m deep, according to Irene Rummelhoff, the executive vice president for new energy solutions at Statoil, speaking at a webcast press conference announcing that the new wind farm would be built. Fixed offshore wind farms, on the other hand, are limited to depths of 50 m. (See, for example, "Largest Offshore Wind Farm Powers Up Near London," Civil Engineering online, April 30, 2013)

Developing a viable, commercial-scale floating wind farm will "open up a tremendous amount of new wind resources for commercialization," said Rummelhoff. This potential will prove particularly valuable to such nations as Japan and the United States, where deep water and strong winds are abundant, she noted.

"In the U.K. there is a need for new capacity in the electricity market as aging power plants are taken off-stream, and in Scotland, the wind and ocean conditions for floating are excellent," said Elin A. Isaksen, a press spokesperson for the Stavanger, Norway-based Statoil, who wrote in response to questions posed by Civil Engineering online.

While the average wind speed in the Buchan Deep is 10.1 m/s and the average wave heights are 1.8 m, a test turbine that Statoil has been monitoring for six years in the North Sea has proven successful in far harsher conditions. That prototype was installed off the island of Karmøy in Norway and has successfully experienced 44 m/s winds and 90 m wave heights, according to Steven Bull, the senior vice president of offshore wind and carbon capture and storage at Statoil, who also spoke at the press event.

The prototype had 200 measurement points so that its design could be tweaked as necessary over the years to create optimum performance, Bull noted. The pilot park will enable the prototypes to be further adjusted; they will be monitored to determine how they interact with one another, according to Isaksen.

Massive—yet relatively straightforward—floating turbines will be used for the park, according to Bull. "The simplicity of the high-wind design is what makes it so genius," he said. An 80 m tall spar-type buoy will float in the water, weighted with water and moored to the seabed with a three-line mooring system. (This spar-type buoy is established technology that is already in regular use, Bull noted). The buoy will be topped with a 178 m tall turbine structure with a rotor span of 154 m, a width that is the equivalent to the length of 2 ½ soccer fields, according to Bull. A patented motion-control system will reduce fatigue and increase production of the turbines.

But the size of future turbines could outstrip these existing iterations.

"Estimating the optimum size of offshore turbines is challenging," said Isaksen. "In general, bigger is better, as the infrastructure and operations costs will be reduced," she said. "But with increasing size, the logistics will become more challenging." This includes the difficulty of transporting and lifting very long blades, for example, and the fact that some types of floating windmill designs are more adaptable to being scaled up than others. "We haven't yet concluded what the optimum size of floating will be, but we are very confident it will be possible to increase the scale beyond current state-of-the-art turbines," Isaksen said.

Since 2009, Statoil has seen the cost per MW for floating turbine technology drop by 60 to 70 percent. Statoil expects that the cost will be reduced by an additional 40 to 50 percent by 2030, making it possible for floating wind-generating technology to become competitive with fixed offshore wind farms, as well as with any next-generation sources that have yet to be developed.

The pilot park is expected to be producing wind energy for an expected 20,000 homes by late 2017.

|

VER TODAS

LAS NOTICIAS

Afiliación Afiliación

Formularios Formularios

|